Newswise — From construction to operation and maintenance, a young Chicago veteran has his fingerprints all over a nuclear research facility at Argonne.

Chicago native Danny Andujar didn’t set out to work in nuclear energy. After high school graduation, he joined the U.S. Marines Corps and trained as a Humvee mechanic before joining an active combat unit in Iraq. Following that tour, he returned to his hometown and applied his mechanical skills at a company that used a process involving sodium to make titanium powder. The job gave him experience with sodium-wetted pumps, valves, vessels and loops — all the same infrastructure that he now uses daily as a critical member of a small team advancing some of the nation’s most cutting-edge nuclear reactor research.

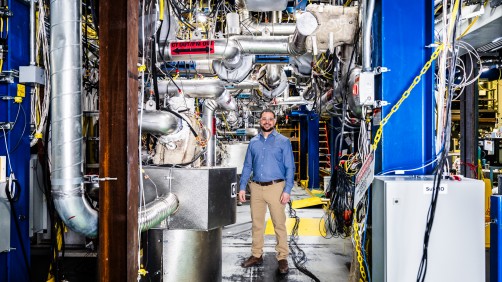

Andujar is an experimental facility operator at the U.S. Department of Energy’s (DOE) Argonne National Laboratory’s Mechanisms Engineering Test Loop (METL) facility. Wearing the familiar uniform of an industrial or automotive mechanic, he makes possible studies that impact the worldwide scientific research and development community, the U.S. nuclear industry and most Americans. The METL facility conducts research for advanced reactors, a nuclear technology that can produce large amounts of carbon-free power and lighten U.S. reliance on non-renewable energy sources, such as oil and gas.

“I love working under pressure,” Andujar said with a smile and something of a shrug. “I think I learned that in the Marine Corps. When things are chaotic for other people, I function and get things done.”

Derek Kultgen, group leader of the METL team, was one of the early team members who initially interviewed Andujar for his current role at Argonne. At the time, in 2016, the METL facility was under construction. The two men talked and walked together through the as-yet-unfinished facility, and Kultgen was impressed that much of the equipment was already familiar to Andujar.

“I love working under pressure. I think I learned that in the Marine Corps. When things are chaotic for other people, I function and get things done.” — Danny Andujar, Argonne National Laboratory

“Danny had alkali metal handling expertise and techniques from his previous job,” Kultgen remembered. “That’s one reason he’s been able to do so many things necessary for running a holistic and state-of-the-art alkali metal research program.”

Aside from familiarity with instrumentation and alkali metal handling experience, Andujar brought additional skills that served the METL team well as it went through the construction phase to actual operation. Like any construction project, METL needed professionals trained in carpentry, welding, tubing and insulation installation, as well as qualified electrical work. Andujar helped in all these areas, and with thermocouple installation, sensor integration, schematics and wiring. Lots and lots of wiring.

“Danny ran thousands of feet of instrumentation cabling, equipping components with heaters and sensors, routing raceway, tubing and other infrastructure,” Kultgen said.

All this work made possible experiments that focus on reactor-grade molten sodium. Sodium is a coolant that may help future reactors produce carbon-free nuclear energy more efficiently with less waste. The METL facility contains four distinct vessels in which researchers can test advanced reactor system and component technology development. The METL sensors — maintained and operated by Andujar and the team — monitor fluctuations in temperature as sodium circulates. METL provides insight to the performance of industrial components inside an environment very similar to that of a sodium-cooled nuclear reactor. Additionally, next-generation nuclear scientists, engineers and technicians gain better understanding of the design, construction, maintenance and operation needs of advanced nuclear reactors based on experiences at METL.

Today, Andujar focuses on operations and maintenance instead of construction. That involves monitoring purifications operations, performing inspections and addressing equipment calibrations. He inventories any sensitive materials used at METL and contributes to design discussions.

Importantly, he supports the addition of new test vessels to METL’s existing infrastructure. This is partly necessary because of METL’s growing clientele base, and it’s also because one pioneering experiment often leads to a subsequent experiment.

For example, in the Thermal Hydraulic Experimental Test Article (THETA) experiment, Principal Engineer Matt Weathered simulated a sodium-cooled nuclear reactor with an electrically heated core. Weathered designed the experiment and then worked with Andujar to put it all together.

“I did the wiring, connections and thermocouple installation on THETA,” Andujar said. “Matt’s the brains, but my fingerprints are all over that one.”

Recently, Weathered designed and commissioned a secondary system for THETA that removes heat. THETA will help simulate a variety of operating conditions characteristic of a full-scale reactor so that researchers can collect experimental data to help inform safer, more efficient designs. Andujar worked closely with Weathered to make that experiment a reality.

“Danny has been a key member for the expansion of METL,” said Chris Grandy, Argonne’s lead of advanced technology development in nuclear science and engineering. “METL is a good facility to have people like Danny working with you and you can rely on him 100%.”

In fact, Andujar doesn’t speak in the singular when he talks about work at METL. “We did the resistance testing on the heater.” “We got QEW2 certification.” “The testing we are doing would generate codes for real-world use.” Emphasis on collective effort is a way of thinking that he says carried over from his time in the Marines. His focus is the shared mission, first in the Marines, and now at Argonne and at METL.

“It’s never just me, me, me,” Andujar said. “It’s the team.”

To arrive at his more individual interests, one has to ask Andujar about a completely different but similarly complex system: exotic animal life. Specifically, colorful ambanja and ambilobe panther chameleons and their habitats.

“I pick up hobbies that push me to learn and overcome certain stuff,” he said. “I do tons of deep research and watch YouTube videos so I can figure things out.”

Andujar is raising 11 hatchlings that can change to green, blue, red or yellow. He orders their cages online and plumbs his own nozzles to create sprayers that simulate the tropical rain forests of Madagascar. Habitats are kept perfectly controlled at a humidity of 50% or above, and Andujar carefully seeks out and provides the specific plants that ambanjas and ambilobes need to thrive. The reason for all this personal mettle?

“Animals are unique and so awesome to have,” Andujar said. “I love to do my own work. It drives me.”

METL is funded under the DOE, Office of Nuclear Energy’s National Reactor Innovation Center for operations and maintenance and its Advanced Reactor Technology program for research and development.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation’s first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America’s scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy’s Office of Science.

The U.S. Department of Energy’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.

MEDIA CONTACT

Register for reporter access to contact detailsArticle Multimedia

Credit: (Image by Argonne National Laboratory.)

Caption: Danny Andujar, an experimental facility operator at Argonne, is an integral member of the METL facility team.

Credit: (Image by Argonne National Laboratory.)

Caption: Andujar’s responsibilities include monitoring purifications operations, performing inspections and addressing equipment calibrations. He inventories sensitive materials used at METL and contributes to design discussions.

Credit: (Image by Argonne National Laboratory.)

Caption: Andujar saw the METL facility through its construction phase and into an exciting maintenance and operations phase. He supports the addition of new test vessels to METL’s existing infrastructure.